Many startup teams begin looking for a co-manufacturer when early sales outgrow a home kitchen, pilot plant, or small-scale production setup. In today’s crowded CPG manufacturing landscape, emerging brands must move fast, stay lean, and produce consistently to compete with national players. Working with a skilled co-manufacturer allows brands to scale smoothly without investing in equipment, staffing, or facilities before they are ready.

A strong CPG contract manufacturer can bridge the gap between startup-level production and full-scale commercialization, giving young brands the innovation support, flexibility, and capacity they need to grow.

What a Co-Manufacturer Does for Emerging CPG Brands

A co manufacturer is a production partner that manufactures products according to the brand’s formula and specifications. For emerging CPG manufacturing teams, this support often includes:

- Blending or mixing

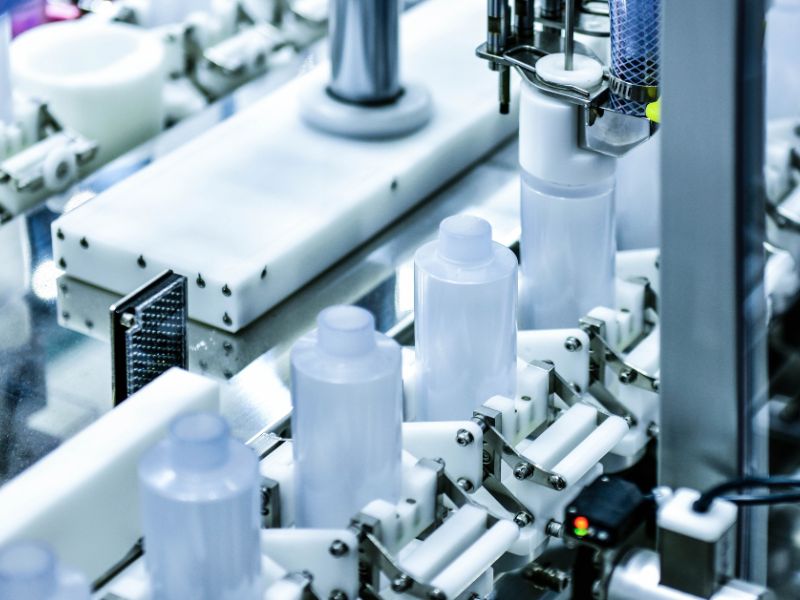

- Automated or semi-automated filling

- Flexible packaging formats

- Quality control and compliance oversight

- Clean room processing for sensitive formulas

- Fulfillment, warehousing, or distribution assistance

- Engineering guidance for scaling recipes

Most importantly, co manufacturing helps brands build reliable operational foundations long before they invest in their own facilities.

Why Co-Manufacturers Are Essential for Startup and Mid-Market CPG Brands

As consumer expectations rise and retail shelves become more competitive, growing brands need production partners who can help them scale quickly without sacrificing quality.

Here are the top benefits for emerging brands.

1. Low Minimum Order Quantities (MOQs)

Many early-stage brands are not ready for full-scale production. They need batch sizes that allow them to test demand, manage cash flow, and avoid carrying excess inventory.

Co manufacturers that specialize in emerging brands offer:

- Low MOQs

- Pilot runs

- Small-batch capabilities

- Scalable pathways to larger volume

This helps startups launch confidently without overextending financially.

2. Faster Time to Market

Emerging brands must move fast to capture attention and secure retail placements. Co manufacturers already have the equipment, processes, and operators in place to begin production quickly.

This reduces time spent on:

- Sourcing equipment

- Hiring production staff

- Setting up facility processes

- Managing compliance operations

Speed is often the competitive advantage that helps young brands break through.

3. Flexible Capacity for Growth

Startups rarely grow at predictable rates. Co manufacturers provide flexible capacity that expands or contracts based on demand.

This flexibility supports:

- Seasonal surges

- New account wins

- E-commerce volume spikes

- Retail promotions

- Rapid growth phases

Brands gain scalability without the cost of owning equipment that may sit idle between runs.

4. Operational Expertise and Support

Emerging brands often lack in-house production expertise. A co manufacturer provides experienced operators, QA teams, and engineering support that ensure product consistency.

This expertise includes:

- Filling accuracy

- Correct packaging selection

- Formula scaling

- Quality testing

- Regulatory documentation

- Line efficiency guidance

Reliable support reduces operational risk and strengthens brand credibility.

5. Innovation Support for New Products

A strong co manufacturer can help brands refine formulas, test packaging formats, and validate product functionality at scale.

This may include:

- Adjusting viscosity or texture

- Improving blend uniformity

- Advising on packaging compatibility

- Running trial batches

- Helping shift from manual to automated production

Innovation is easier when brands are not limited by equipment or internal production constraints.

6. Lower Capital Requirements

Building a facility or purchasing equipment requires significant investment, and most emerging brands cannot take on that kind of financial risk early on. Co manufacturing eliminates:

- Equipment purchases

- Maintenance expenses

- Staffing and training costs

- Facility expansion

- Utilities and overhead

This keeps the brand’s budget focused on marketing, distribution, and growth.

7. Stronger Quality Systems and Compliance

Retailers expect consistency, traceability, and strong QA standards. Co manufacturers already operate with the systems emerging brands need to scale safely.

Quality protections may include:

- Lot tracking

- Sample retention

- Metal detection

- Checkweighing

- Clean room production

- Documented SOPs

- Batch reporting

These systems help young brands meet retailer and regulatory expectations without building internal QA teams.

What Emerging Brands Should Look for in a Co-Manufacturer

Not all co manufacturers are the right fit for early-stage brands. Look for a partner who offers:

- Low or mid-range MOQs

- Experience with your product type

- Multiple packaging formats

- Automated filling capabilities

- Responsive communication

- Scalable capacity

- Clear pricing structures

- Strong QA processes

- A collaborative approach

Emerging brands need a partner who acts as an extension of their operations, not just a vendor.

How MaxUS Supports Growing CPG Brands

MaxUS is built to support startup and mid-market brands that need flexibility, speed, and consistency. We focus on scalable systems and hands-on partnership that help young brands grow confidently.

We provide:

- Blending and mixing for powders, liquids, pastes, and granules

- Flexible packaging options including pouches, jars, bottles, stick packs, and sachets

- Clean room production for sensitive items

- Automated and semi-automated filling

- Low to high volume production capabilities

- Retail ready and bulk packaging

- Fulfillment and distribution support

- Quality assurance across every run

Whether you are launching your first SKU or preparing for national distribution, MaxUS supports your growth with operational strength and strategic flexibility.

Key Takeaways

- Co manufacturers help emerging CPG brands scale with low MOQs, fast timelines, and reliable quality systems.

- Outsourcing production reduces capital risk and improves long-term agility.

- Co manufacturing supports innovation, expansion, and operational stability.

- MaxUS provides flexible, scalable solutions designed specifically for growing CPG brands.

If your emerging CPG brand needs a co manufacturer who supports innovation, growth, and flexibility, MaxUS is here to help. Our systems and expertise give young brands a strong operational foundation from day one.Connect with our team to explore a co manufacturing strategy built for your stage of growth.