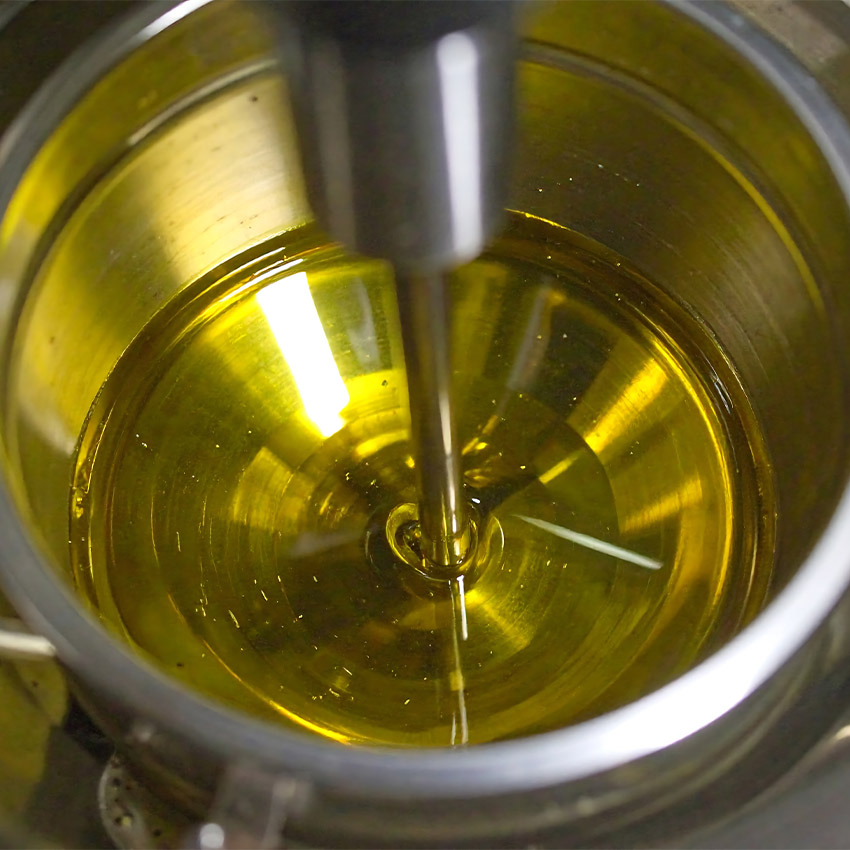

Achieving the right blend is crucial for maintaining product quality and consistency. At MaxUS, we offer blending of powders and liquids as part of our turnkey contract packaging services. Sometimes called powder mixing or liquid mixing, this process combines raw ingredients into uniform batches that are ready for filling, packaging, and distribution.

You should consider contract blending services if:

- You need custom formulations blended for food, beverages, supplements, or industrial products.

- You want to outsource powder or liquid mixing to save on equipment costs.

- You need a partner who can handle sensitive ingredients with precision and consistency.

- You are preparing pilot runs or large-scale production and need scalable blending solutions.

At MaxUS, we specialize in blending powders, liquids, and even complex ingredients like super-thick surfactants and sensitive formulations. Our expertise ensures your products are mixed thoroughly, packaged correctly, and compliant with industry standards.

Benefits of Blending of Powders & Liquids

- Achieve consistency with uniform mixing across every batch.

- Support custom formulations for food, beverages, supplements, and industrial products.

- Save costs by outsourcing blending instead of investing in specialized equipment.

- Handle sensitive ingredients with precise techniques for powders and liquids.

- Scale production easily from small pilot runs to high-volume orders.

- Ensure compliance with industry standards for quality and safety.

What Products Use Blending Services?

- Food & Beverages – drink mixes, sauces, concentrates, and flavor blends.

- Nutraceuticals & Supplements – protein powders, capsules, and liquid formulations.

- Personal Care & Cosmetics – lotions, creams, shampoos, and powdered beauty products.

- Household Products – detergents, cleaners, and other blended concentrates.

- Pet Products – powdered supplements, liquid additives, and nutrient blends.

- Industrial Goods – adhesives, lubricants, surfactants, and specialty chemicals.

When to Use Blending of Powders & Liquids in Contract Packaging

- When you need custom formulations created for food, supplements, or industrial goods.

- When your product requires precise powder or liquid mixing for consistency.

- When you want to scale production from pilot batches to full-scale runs.

- When you need to handle sensitive ingredients that require careful blending.

- When you are launching a new product line and want a turnkey blending and packaging solution.

- When you want to avoid costly equipment investments by outsourcing to a contract blending partner.

FAQ: Blending

1. Can you blend both powders and liquids in the same facility?

Yes. MaxUS facilities are equipped to handle both powder blending and liquid mixing under strict compliance standards.

2. How do you prevent cross-contamination when blending?

Dedicated equipment, controlled environments, and thorough cleaning protocols ensure product integrity.

3. Can you add fragrances or flavors during blending?

Yes. We can incorporate fragrances, flavorings, or other additives to match your formulation needs.

4. Is outsourcing blending cost-effective for small runs?

Yes. Contract blending saves you from investing in expensive mixing equipment and staff training.

5. What industries use blending services the most?

Food, beverages, supplements, personal care, household products, and industrial goods all require powder and liquid blending.

Partner With MaxUS for Blending of Powders & Liquids

The right blend makes the difference between an average product and one your customers trust. At MaxUS, we provide contract blending services for powders and liquids as part of our turnkey packaging solutions. From sensitive raw materials to high-volume production runs, our team delivers consistency, compliance, and scalability at every step.

Whether you are launching a new supplement, expanding a food or beverage line, or producing industrial blends, MaxUS ensures your ingredients are mixed precisely and packaged for success.

Ready to bring consistency and quality to your next batch?