FILLING – BLENDING – MIXING

At MaxUS, we have years of experience handling a wide array of product types. From liquids and pastes, powder and granular items, to solid products we have the expertise and experience to handle your product the most efficient way possible. We have all types of equipment from standard combination scales, augers, and volumetric fillers, to our innovative multiple dosing line to fill up to 6 products with precise accuracy.

When you need products packaged consistently, safely, and at scale, filling, blending, and mixing services are the foundation. At MaxUS, we provide turnkey solutions that handle powders, liquids, and custom formulations in both food-grade clean rooms and non-food environments.

Filling, blending, and mixing is the process of preparing raw materials into a precise, uniform product that’s ready for packaging. This includes powders, liquids, and granules. Companies turn to contract providers like MaxUS when they need:

- Small-batch test runs for new product launches.

- Large-scale production support when in-house lines are at capacity.

- Food-grade clean room handling to meet compliance requirements

- Custom formulations that require specialized mixing or blending expertise.

- Flexible packaging options (pouches, bottles, tubs, sachets, and more).

For startups, outsourcing this process eliminates the need to invest in costly equipment before they’re ready to scale. For CPG manufacturers, it means extra capacity and faster turnaround times without sacrificing quality or compliance.

At MaxUS, we combine industrial-grade equipment, clean room facilities, and scalable systems to ensure your products are blended, mixed, and filled with precision every time.

Non-Food-Grade Filling, Blending, and Mixing

Not every product requires food-grade conditions, but that doesn’t mean quality or consistency can be compromised. At MaxUS, we provide non-food-grade filling, blending, and mixing services designed for a wide variety of industries — from household goods to industrial products.

Our non-food-grade environments give manufacturers the flexibility to handle products that don’t need clean room compliance, while still maintaining strict standards for accuracy, safety, and efficiency. Whether you’re producing detergents, adhesives, powders, or specialty chemical blends, outsourcing to MaxUS means you get professional equipment, scalable production, and a team experienced in handling diverse formulations.

Companies turn to non-food-grade filling and blending when:

- Their product doesn’t require food-safe certifications.

- They need extra production capacity outside their in-house facilities.

- Specialized industrial mixing or packaging formats are required.

- They want to scale quickly without major capital investments.

For both startups and established CPG manufacturers, MaxUS offers the flexibility to run small pilot batches or high-volume production — all with the same focus on precision and reliability.

Liquid & Paste Products

From everyday household goods to specialty industrial solutions, liquid and paste products require precise handling to ensure consistency, safety, and performance. At MaxUS, we offer filling and blending services designed specifically for liquid detergents, sanitizers, concentrates, cleaning products, and personal care items.

Product Examples

Our non-food-grade facilities are equipped to manage a wide range of liquid and semi-viscous products, including:

- Liquid detergents

- Sanitizers

- Concentrates

- Cleaning products

- Personal care items

Filling & Blending Capabilities

We use a variety of specialized filling and blending equipment to meet the needs of different viscosities and formulations:

- Volumetric fillers for precise product measurement.

- Gravity fillers for efficient handling of thin or free-flowing liquids.

- Liquid blending systems that combine ingredients into uniform solutions.

- Heating, agitation, and other blending features to maintain product quality and stability during processing.

By combining the right equipment with industry expertise, MaxUS ensures your liquid and paste products are filled, blended, and packaged with accuracy, speed, and scalability — whether you need a small pilot run or a large-volume production cycle.

Powder & Granular Products

Powdered and granular products demand precise measurement, controlled blending, and dust-safe handling to maintain product quality and consistency. At MaxUS, our non-food-grade facilities are equipped with the right technology and expertise to handle everything from household powders to complex industrial formulations.

Product Examples

We provide filling and blending services for a wide range of powder and granular applications, including:

- Powder detergents

- Industrial products

- Cleaning products

- Personal care items

Filling & Blending Capabilities

Our systems are designed to deliver consistent fill weights, uniform blends, and scalable production for powders and granules. Capabilities include:

- Volumetric fillers for accurate and efficient dispensing.

- Auger fillers for precise dosing of powders and fine granules.

- Powder blending systems, including:

- Ribbon blenders for thorough, continuous mixing.

- Tumbling blenders for gentle, uniform blending of sensitive materials.

With the right equipment and a team experienced in handling dry goods, MaxUS ensures your products are blended, filled, and packaged to meet the demands of both pilot runs and large-scale production cycles.

Solid Products

Solid products often require specialized handling and precision weighing to ensure consistency in every package. At MaxUS, we support a wide range of solid product applications — from cleaning tablets to custom kits — using equipment and processes designed for both accuracy and efficiency.

Product Examples

Our non-food-grade filling and blending services cover a variety of solid products, such as:

- Product additives

- Cleaning tablets

- Kits and assemblies

- Additives and ingredients

- Art supplies

Filling & Blending Capabilities

To meet the unique demands of solid product packaging, we utilize equipment and processes built for versatility and precision:

- Computer combination weighers (10, 14, 20 & 24 heads) for highly accurate portioning.

- Volumetric fillers for consistent measurement.

- Gravity fillers (continuous) for efficient throughput.

- Tumbling mixing for even distribution of ingredients or additives.

With MaxUS, you get more than just production support — you get a partner who ensures your solid products are measured, blended, and packaged reliably, whether you’re running small pilot batches or high-volume production lines.

Food-Grade Filling, Blending, and Mixing

When it comes to food, beverage, nutraceutical, and supplement products, precision and compliance are not optional. They are essential. That’s why MaxUS provides food-grade filling, blending, and mixing services in facilities designed to meet strict safety and regulatory standards.

Our clean room environments control air quality, temperature, and contamination risk. This ensures your products are handled according to industry regulations such as ISO, SQF, and FDA guidelines. From powders and liquids to additives and concentrates, we have the expertise and equipment to maintain the integrity, safety, and consistency of every batch.

Companies rely on food-grade blending and filling in the following situations:

- Their products must meet regulatory standards for safety and cleanliness.

- They need nutraceutical or supplement packaging with precise dosing.

- Consistency and quality directly impact brand reputation and consumer trust.

- They are scaling up production and need to ensure compliance at higher volumes.

Whether you are a startup launching a new supplement line or a CPG leader producing millions of units, MaxUS delivers turnkey food-grade packaging solutions that protect your product and your reputation.

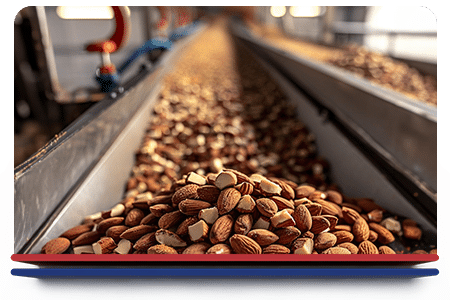

Solid Products

Food-grade solid products require careful handling, accurate weighing, and consistent blending to maintain product quality and meet safety standards. At MaxUS, we specialize in filling and blending services for a wide variety of solid food and supplement products, from snacks to tablets.

Product Examples

Our facilities are equipped to manage both small and large-scale runs of food-grade solids, including:

- Candy and confectionery

- Wrapped, unwrapped, and gummy candies

- Snack items such as pretzels, chips, nuts, grains, and granola

- Pet foods

- Pills, tablets, and capsules

Perfect for seasonal items and snack mixes

Filling & Blending Capabilities

We use advanced equipment to ensure accurate dosing, consistent blends, and scalable production for solid food products:

- Computer combination weighers (10, 14, 20, and 24 heads) for precise portioning.

- Volumetric fillers for reliable measurements.

- Gravity fillers (continuous) for efficient throughput on high-volume items.

- Tumbling mixing for uniform distribution in snack mixes and blended products.

With MaxUS, you can trust that your solid food products are filled and blended with accuracy, safety, and scalability, whether you are preparing seasonal snack mixes or running continuous high-volume production.

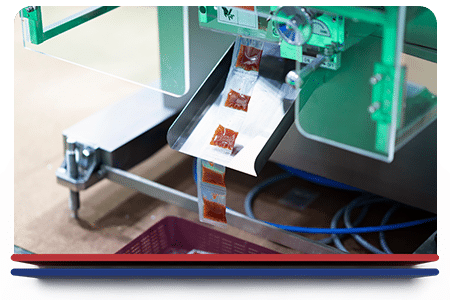

Multi-Product Filling

Some products require more than one ingredient in a single package. MaxUS offers multi-product filling services with the ability to accurately dose and fill up to six different products into the same package. This capability is ideal for snack mixes, variety packs, and seasonal items that combine multiple components.

Why Multi-Product Filling Matters

- Ensures accurate dosing of each product type.

- Maintains product consistency and quality control across every package.

- Reduces manual labor by combining products in a single, efficient process.

- Adds flexibility for seasonal or limited-edition packaging.

Perfect for Seasonal & Specialty Items

Multi-product filling is especially popular for:

- Halloween candy assortments

- Holiday snack mixes

- Variety packs for retail or promotional launches

By leveraging advanced weighing and dosing technology, MaxUS makes it possible to bring creative, multi-component products to market quickly and with confidence.

Liquid & Paste Products

Food-grade liquid and paste products require specialized equipment and strict compliance with safety standards to ensure consistency, freshness, and quality. At MaxUS, we provide filling and blending services for beverages, sauces, concentrates, and more, all within environments designed to meet ISO, SQF, and FDA guidelines.

Product Examples

Our food-grade facilities can handle a variety of liquid and semi-viscous products, including:

- Beverages

- Condiments and sauces

- Pet foods

- Concentrates

Filling & Blending Capabilities

We use advanced systems to ensure accurate filling, smooth blending, and consistent product quality:

- Volumetric fillers for precise portioning.

- Gravity fillers for efficient handling of free-flowing liquids.

- Auger filling systems for thicker pastes and semi-viscous products.

- Blending features such as:

- Ribbon blenders for continuous, even mixing.

- Tumbling systems for gentle, uniform blending of delicate materials.

With MaxUS, your liquid and paste products are filled and blended using equipment that ensures accuracy, scalability, and regulatory compliance, whether you are producing small test batches or large-scale retail-ready runs.

Powder & Granular Products

Food-grade powder and granular products require precise handling to ensure accurate dosing, uniform blending, and compliance with strict safety standards. At MaxUS, we specialize in filling and blending services for everything from protein powders to soup mixes, helping both startups and established CPG brands bring high-quality products to market.

Product Examples

Our food-grade facilities can handle a wide range of powdered and granular applications, including:

- Protein powders

- Nutraceuticals and supplements

- Chocolate powders

- Food additives

- Soup and broth mixes

Filling & Blending Capabilities

We use advanced equipment to ensure consistency, compliance, and scalability for powder and granular products:

- Volumetric fillers for precise portioning.

- Gravity fillers for efficient handling of free-flowing materials.

- Liquid blending systems for products requiring incorporation of wet ingredients.

- Product heating, agitation, and additional blending features to maintain product integrity during processing.

With MaxUS, your powdered and granular products are filled and blended with precision, safety, and scalability, whether you need small pilot runs for a new formula or high-volume production for established product lines.

Partner With MaxUS for Filling, Blending, and Mixing

Whether you are a startup testing your first product run or a CPG manufacturer scaling for national distribution, MaxUS delivers the flexibility, compliance, and precision you need. Our turnkey approach to filling, blending, and mixing gives you access to food-grade clean rooms, scalable systems, and industry expertise — all designed to bring your product to market quickly and with confidence.

With MaxUS, you gain a partner who understands that every product, every formula, and every run matters. From powders and liquids to solids and multi-product packaging, we provide the accuracy, safety, and speed that keep your business moving forward.

For both startups and established CPG manufacturers, MaxUS offers the flexibility to run small pilot batches or high-volume production, all with the same focus on precision and reliability.