Many brands seeking a co-manufacturer do so because they need more capacity, speed, or flexibility than their internal operations can provide. Co-manufacturing is one of the most effective ways to scale production without investing in new equipment, hiring additional staff, or building out new facility space.

As demand grows and product lines become more complex, CPG manufacturing requires partners who can adapt quickly and produce at the level your customers expect. That is exactly where co-manufacturing becomes an invaluable strategy.

What Is Co-Manufacturing

Co-manufacturing is a partnership in which an external producer manufactures products on behalf of a brand. This partner, known as a co-manufacturer, provides the equipment, labor, expertise, and facility required to produce finished goods based on the brand’s formula or specifications.

Co-manufacturing is widely used in:

- Food and beverage

- Supplements and nutrition

- Beauty and personal care

- Household goods

- Specialty and industrial products

A strong CPG manufacturer brings together engineering, quality assurance, production management, and packaging capabilities to create a complete, scalable solution.

Why Brands Use Co-Manufacturing

Brands choose co-manufacturing because it helps them grow faster while maintaining control over their product identity.

Key benefits include:

Faster Scaling

A co-manufacturer already has the equipment and workforce in place. Brands can increase production quickly without long lead times.

Cost Efficiency

There is no need to invest in new lines, hire new staff, or expand facility space. Teams avoid major capital costs.

Higher Production Flexibility

Co-manufacturing partners can handle multiple SKUs, frequent line changes, seasonal volumes, and different package sizes.

Operational Stability

Instead of relying only on internal lines, brands add redundancy and protection against equipment failures or staffing shortages.

Access to Expertise

Experienced operators, engineers, and QA specialists ensure consistent output and regulatory compliance.

Co-manufacturing is more than outsourcing. It is a way to build operational resilience and to focus internal teams on innovation rather than on daily production demands.

How A Co Manufacturer Works

Although process details vary by product, co-manufacturing generally follows a structured workflow that supports predictability and quality.

1. Product Intake and Specification Review

The co manufacturer begins by reviewing:

- Formulas and ingredient lists

- Packaging requirements

- Production volumes

- Target timelines

- Compliance needs

- Quality expectations

This step ensures the partner can support your product safely and efficiently.

2. Sourcing and Material Coordination

Depending on the agreement, either the brand or the co-manufacturer sources raw materials and packaging. The partner ensures that materials meet required standards and flow smoothly through the production line.

3. Blending or Mixing

Most CPG manufacturing requires preparation before filling. This can include:

- Powder blending

- Liquid mixing

- Temperature-controlled processing

- Viscosity adjustments

- Homogenization

Clean rooms may be used for sensitive or highly regulated products.

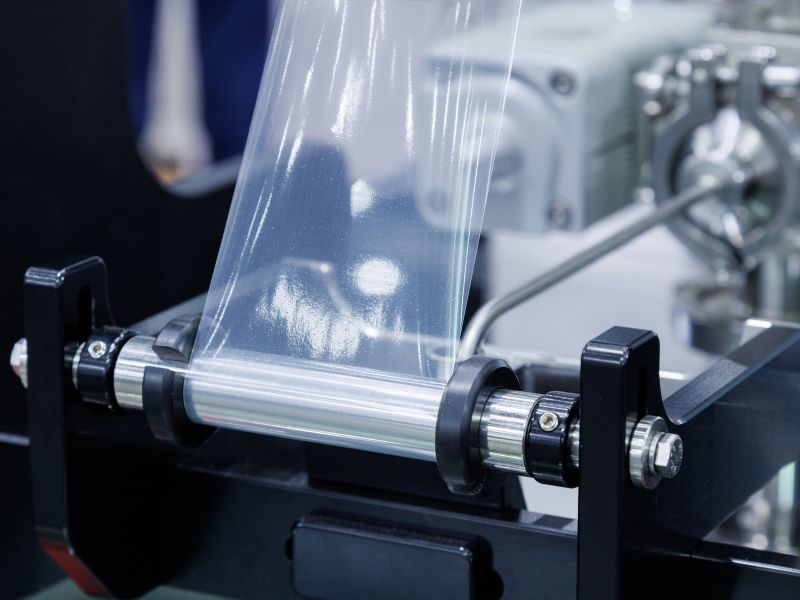

4. Filling and Packaging

This is where the product becomes retail-ready. Co-manufacturing partners support a wide range of formats, such as:

- Pre-made pouches

- Stick packs and sachets

- Bottles, jars, and tubs

- Bulk containers

- Single-serve and multi-serve packages

Automated and semi-automated lines ensure accurate filling and consistent packaging.

5. Quality Assurance and Compliance

A strong co-manufacturer incorporates quality checks throughout the process. This may include:

- Lot tracking

- Metal detection

- Checkweighing

- Label and seal verification

- Sample retention

- Documentation for audits and retailers

These systems protect your brand and ensure product safety.

6. Final Packing and Fulfillment Support

Once packaging is complete, finished goods are prepared for storage or distribution. Some co-manufacturing partners, such as MaxUS, also offer warehousing and fulfillment support to keep the supply chain streamlined.

When to Choose A Co Manufacturer

Co-manufacturing is ideal when:

- You are outgrowing your internal capacity

- You want to expand into new markets or categories

- You need a partner with specialized equipment

- Your team is stretched thin

- You experience variable or seasonal demand

- You want a more efficient cost structure

- You need reliable operational support

Brands gain both short-term relief and long-term scalability.

How MaxUS Supports Co-Manufacturing Partnerships

MaxUS brings together precise engineering, hands-on partnership, and flexible production systems to support CPG manufacturing at every stage. Our team offers:

- Blending and mixing for powders, liquids, pastes, and granules

- Pouch, stick pack, bottle, and jar filling

- Clean room production

- Automated and semi-automated lines

- Retail-ready packaging

- Bulk packaging for B2B clients

- Fulfillment solutions to complete the process

We focus on building strong, collaborative relationships that help brands scale with confidence and maintain product integrity.

Key Takeaways

- A co-manufacturer produces goods on behalf of a brand using the brand’s formulas and specifications.

- Co-manufacturing offers faster scaling, lower costs, and greater production flexibility.

- The process includes intake, sourcing, blending, filling, packaging, and QA.

- MaxUS provides flexible, high-quality co-manufacturing solutions designed for growth.

If your team is looking for a co-manufacturing partner that delivers both speed and precision on every production run, MaxUS can help. Our flexible systems and collaborative approach support brands that need to scale quickly while maintaining consistent quality.

Connect with our team to explore how co-manufacturing can support your next phase of growth.